Our Inquiry Form

Reverse Osmosis (RO) is a process of physical separation of dissolved solids and minerals present in water. This RO water plant technology uses the principle of osmosis, wherein the mineral concentration of raw water is reduced by applying high pressure through a semi-permeable membrane.

RO technology offers maximum flexibility to meet diverse requirements. Our customised software, INDIAN helps customers gain the maximum ‘RO Advantage’, by helping to make the right selection.

INDIAN considers your inlet water quality and capacity requirements and offers you optimised combination. This choice is dependent on different flux rates, pump models, membrane types and inlet water quality. It gives the right solutions, reduced

ADVANTAGES OF RO WATER PLANT

- Compact and modular RO blocks

- Easy installation, operation and servicing

- Specific selection possible from a wide range

- High level of plant automation

- Visual monitoring system (VMS) for ease of trouble-shooting

- Stainless steel multistage centrifugal pump; inline suction and delivery allows easy maintenance and access

- Online product water quality monitoring

- Membrane and pump protection features

- ‘RO Advantage’ enhanced through INDIAN

- Minimum pipe length to reduce system resistance

- Easy servicing with QRC (Quick Release Coupling)

- Material of construction: PVC/SS

INTRODUCTION OF “PRINCIPLE OF REVERSE OSMOSIS”

Reverse Osmosis (RO) is the process, in which water is pressurized through a semi –permeable membrane. As a result of this, as shown in the below depicted schematic diagram, water will pass through the membrane surface while the dissolved and particulate materials are left behind. When the pressure is applied to the concentrated solution, water is forced through the membrane from the concentrated side to the dilute side. This process is known as “ Reverse Osmosis.”

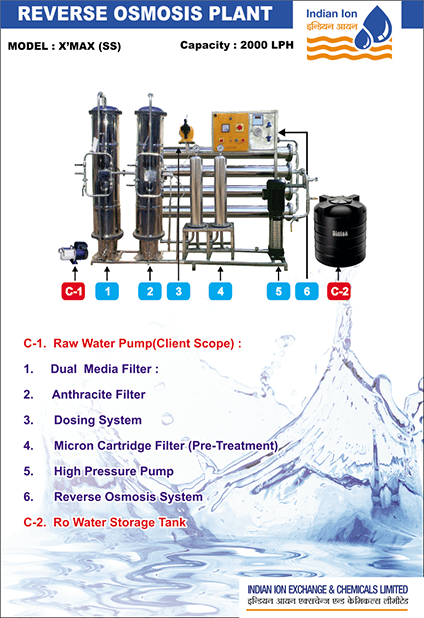

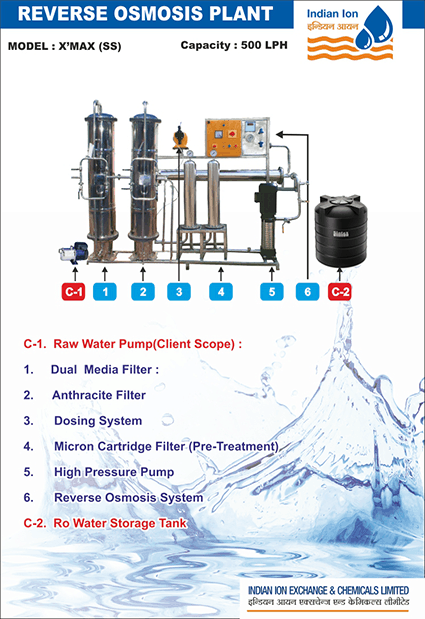

SCHEMATIC DIAGRAM OF RO WATER PLANT SYSTEM

- (A) CONCENTRATED SOLUTION

- (B) DILUTE SOLUTION

The application of Reverse Osmosis to the solution of problems in water treatment requires an understanding of the basic mechanisms involved in the RO water plant process, the limitations of reverse osmosis and the pre treatment requirements.

Reverse osmosis utilizes the unique properties of a “Imported” semi- permeable membrane to allow fluid to pass while restricting the flow of Dissolved Ionic material. With pressure applied to impure water on one side of such membrane materials, pure water will pass through, leaving most of the impurities behind. The rejection of the dissolved ionic material is a function of both Molecular weight and Ionic charge. For example, we can expect a nominal 90 % rejection of Sodium Chloride, which means that the product water passing through the membrane will have a concentration of salt approximately One-tenth that if the feed water. The rejection of calcium carbonate (Hardness) will be nearly 95%. While most metallic salts will be rejected at a rate of 98% to 99%.

The rejection of non- ionic or organic material is primarily done by mechanical filtration.

The RO water plant system is composed of two major parts, High Pressure pump and the R.O. membranes. The initial purified water production rate is measured at this pressure.

It appears that there are long term benefits to be gained by operating at lower percent water recovery, particularly in reducing maintenance to the systems and minimizing precipitation problems which may arise due to operator error.

It is important to realize that the purified water from a Reverse osmosis system is delivered essentially at Atmospheric pressure, usually to a vented storage tank. In general, It cannot be operated by opening and closing valve in the product water line (unless special pressure relief is provided). The reason for this is that the high pressure in the system drives the water across the membrane. And no flow of water would be possible if the pressure on both sides of the membranes were same. If, for some reason, the product water line is closed, while the system is operating, the pressure would build up. Of course, if the purified water side of the system was strong enough, the pressure would end up the same as the pump pressure, but at that point, no water would flow across the membrane. In reality, the P.V.C. piping on the product water side normally would not tolerate such high pressure.

The membrane is capable of taking 600 psi of “forward pressure”. i.e. from the direction of the supply water side to the purified water side. However, they are susceptible for it’s tolerance limit for “ Back Pressure.” I,e, from the direction of purified water side to the supply water side.” So, one should take care while operating the system.

The Quality of purified water produced by Reverse Osmosis process is roughly a constant percentage of the feed water. For example, if the feed water is entering at 50 ppm , the purified water may be about 1 to 2 ppm. (i.e. 96.00 to 98.00% rejection of dissolved minerals.). For another example, when the feed water is entering at 500 ppm, the purified water would be from 10 to 15 ppm. Usually a Conductivity meter Or TDS meter is used to measure the mineral contents.

OUR APPLICATION

- Ceramic

- Chemicals

- Dairy

- Fishing

- Food & Beverages

- Hospital

- Hotel

- Pharma

- Pulp & Paper

- Textile

Request a Quote

Request a Quote